Hydroponic Growing Systems

Hydroponic system design essentially falls under two main categories, the recycling system and the run-to-waste system. Each offers a different method of growing plants in a water-based feeding environment. You can also divide hydroponic systems into their feeding schedules – constant, timed or passive, but in order to cover the main systems as briefly as possible, we’ll be comparing the advantages and disadvantages of the recycling and run-to-waste systems.

Here’s a brief guide to the main systems.

RECYCLING SYSTEMS

The recycling (also referred to as recirculating)system, feeds nutrients to the plants and then recycled back into a central reservoir. The same nutrient is then fed to the plants again and again over the course of several days (via set feed times) until the nutrient is eventually dumped and replaced with fresh nutrient.

There are four commonly available recycling systems that are widely sold. There are many variations of these systems and this information is aimed at providing you, the grower, with a better understanding of how some of the more commonly used systems work.

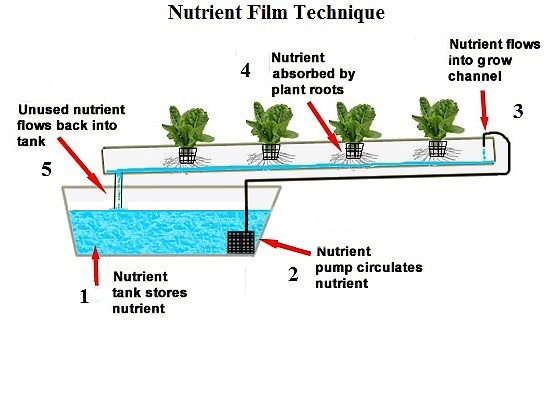

Nutrient Film Technique (NFT)

The NFT system consists of gullies where a thin film of nutrient is constantly recycled through them. Plants are placed in these gullies in small cups containing perlite. The perlite absorbs the nutrient and as the roots grow they enter the gullies. From here they absorb nutrients, quickly developing larger root systems which form on the base of the gullies.

NFT is a very efficient growing system as the constant nutrient feed allows for simple maintainence, with constant root zone temperatures.This greatly aids plant growth with the potential to provide optimum uptake of nutrients.

The main downfall of this system is that NFT channels are relatively narrow and lack the necessary space for large root systems. As the roots fill the space inside the channel they become blocked and the nutrient starts backing up, eventually flooding the gullies. In extreme cases this will lead to oxygen starvation of the root system, i.e. drowning. This is more likely in cases where larger plants are grown in NFT channels. To get round this drawback, there are NFT systems that have been developed specifically for larger plants.This type of system incorporates a wider channel that, in turn, accommodates a larger root system.

Another possible drawback associated to NFT is that it lacks the safety features of media based recycling systems, meaning the lack of media and the constant wetting of the plant’s root system can become a problem in areas prone to high ambient air temperatures. This is because the water/nutrient can become too warm (the warmer the water, the less oxygen it can hold), resulting in low oxygen levels that are available to the plant’s root zone. Once the roots are starved of oxygen they can die quite rapidly.

The NFT system is ideal for cooler climates.

Positives:

- Continuous flow of nutrient reduces incidence of salt build up

- Constant root zone temperatures help to facilitate optimal plant/nutrient up-take

- No media required, reduces running costs and clean up Very good oxygen capacity (based on nutrient temp)

Negatives:

- Plants need to be stabilized due to lack of media

- Prone to heat problems/lack of oxygen to root zones under high heat conditions.

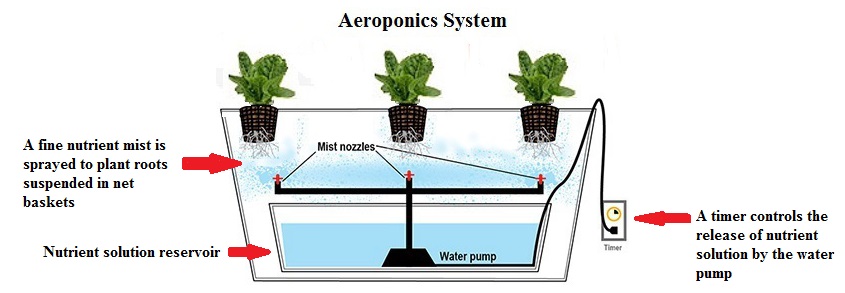

Aeroponics

In an aeroponics system, a plant is generally placed into a small basket with clay pebbles. The basket is then placed into a much larger lightproof tank/large pot (the surface of basket sits flush on the lid of the tank).The tank/large pot does not contain any growing media.

The tank/large pot has a series of spray jets that are used to spray a fine mist of nutrient onto the basket and throughout the inside of the tank/large pot. The mist keeps the growing media in the basket moist (and feeds the plant/s). As the root system of the plant grows it enters the tank/large pot where it hangs freely (in the air environment) and is kept moist by the mist that is emitted from the spray jets.The spray jets, typically, are run 24 hrs a day.

Like the NFT system, the aeroponic system, needs a constantly low root-zone temperature to be maintained to prevent oxygen starvation. Under correct conditions, this can help facilitate explosive growth and in some instances, earlier finishing times.

The aeroponic system, like NFT system, is ideal for cooler climates.

Here is an example of a high quality aeroponic system.

Positives

- Same as NFT system

Negatives

- Same as NFT system

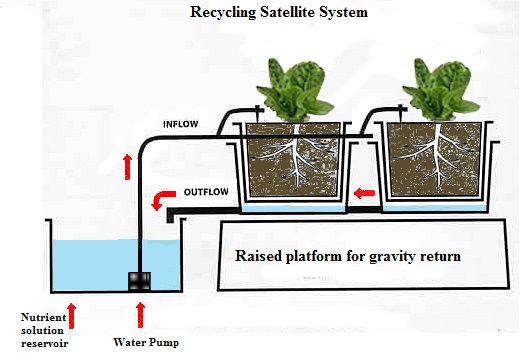

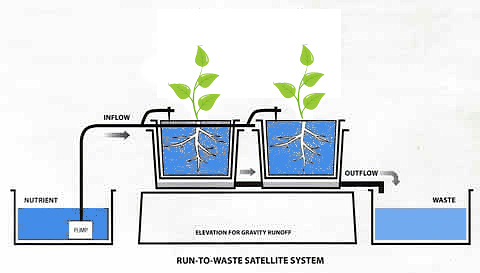

Satellite System

The satellite system is the generic term used for a growing system that consists of multiple pots that each hold one plant.This system can be used with perlite, coco coir, expanded clay, rockwool. or any other growing medium and it is both suitable for recycling and run-to-waste systems. Undoubtedly, it is the most versatile of all the systems if you need to add some plants, simply add new pots to the existing system. To remove a couple of plants that aren’t doing so well, simply remove their pots from the system. There is no decaying root matter left in a single system to create problems for the other plants.This versatility gives the satellite system the ‘growing edge’ over other systems.

Each unit of the satellite system consists of two pots; one of which is placed inside the other leaving a gap for airr and water between the pots.The top pot, which holds the medium, has holes drilled in its base to a allow the nutrient to run into the lower pot.The lower pot has a runoff pipe which feeds back to the reservoir via 19mm hose(usually).

Nutrient is fed via a line from the nutrient tank (approx 15 minutes of feed every 2 hours depending on the medium chosen) to the top pot. This then runs through the top pot, into the bottom pot and back to the reservoir via the 19mm hosing .

The satellite system is ideally suited for larger plants due to its ability to accommodate large root system

Positives

- Very versatile system

- Can be adapted to either run-to-waste or recycling methods of growing and can be used with all growing media

- Cheap to add extra plants to the system (simply add more pots)

- User friendly: growing medium can help preserve the root zones in times of heat. Easy to move plants around due to separate/independent containers

Negatives

- Root zone temps will vary somewhat depending on media type and feed times.

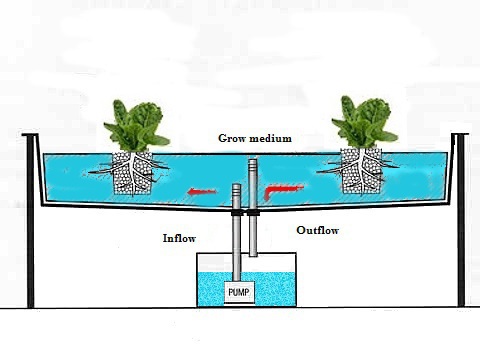

Flood & Drain System

The flood and drain system(sometimes called ebb and flood) is a recycling system that feeds nutrients to the plants from underneath. A Flood and Drain table is setup with two flow regulators, one of which is connected to a pump, the other is set to release the flow of nutrients at 45mm or thereabouts. A reservoir containing water/nutrients sits at one end of the table beneath the flow regulators. A pump in the reservoir feeds water/nutrients upwards into the table.The table floods to a height of approximately 45mm at which point it begins emptying water/nutrients back into the reservoir.

When the pump switches off the remaining water/nutrients drains back into the reservoir (via the pump line) completely

emptying the table.This feed routine should occur for a total of 15 minutes every 2-3 hours.

Plants are placed in. the system in net pots filled with expanded clay.The table itself is at least half filled with clay to ensure the root system has something to grow into. A light-proof material is used to cover the entire top of the table.The lightproof material stops light from hitting the growing medium, eliminating the ability for algae to form on top of the medium. Holes are cut in the material to accommodate the net pots. As the roots grow they enter the growing medium (in the table), eventually forming a dense root mat across the bottom of the table.

Positives

- Typically, less salt build up than many other media based recycling systems due to immersion of the root system during feeds.

- Good aeration where drainage occurs quickly (thus drawing air into the root system)

Negatives

- Where low media levels are concerned, overheating of media can occur quite quickly resulting in low oxygen levels in the media. Because the depth of the average F&D table is minimal this can prove problematic in hot conditions

- Root rot can occur as a result

RUN-TO-WASTE SYSTEMS

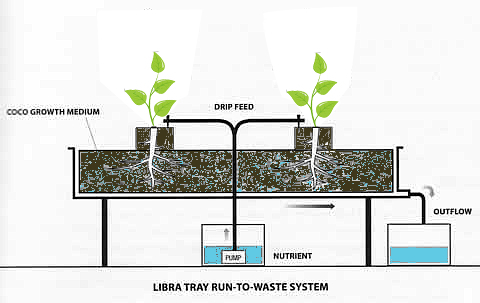

Run-to-waste is the term used for a hydroponics system where nutrients are not recycled (typically) and they use an inert medium that has similar fluid retention rates to that of soil. That is, run-to-waste media retain a high degree of moisture for an extended period. Because of this, feeds are smaller and not as frequent as feeds in a recycling system. In the run-to-waste system plants are given a regulated dose of water and nutrient at such a rate that a small amount of the water/nutrient (average 15-20%) drains from the medium, The excess water and nutrient is then allowed to drain into some form of catchment away from the reservoir. The waste is never fed to the plants again.

Because nutrients are not recycled there are some distinct advantages associated with the run-to-waste system

Advantages

- No nutrient exhaustion as plant receives fresh nutrient at every feed

- pH stability over and above that of recycling systems

- EC Stability (in nutrient tank) over and above that of recycling systems

- Nutrient are less prone to bacteria/pathogen buildup

- Less maintenance

- The run-to-waste system is ideal for larger plants with high uptake needs. Because of the density and fluid retention rates of the medium, the run-to-waste system has security features unmatched by other systems

- Roots are well insulated from heat

- Moisture retention in the chosen medium will last for days, giving the plant/s protection from pump/pump and pump/timer failures. These are very attractive features for experienced growers who know that heat and equipment failures can very easily wipe out a crop

Coco Coir Medium and Nutrients

Coco(nut) Coir is rapidly becoming the medium of choice for run-to-waste enthusiasts. Coco(nut) coir holds eight to nine times its own weight in water and more air than premium brand rockwools. In addition to this Coco coir, unlike rockwool, is bio-degradable which makes it perfect for the garden as a mulch. Coco coir products can vary considerably, so be aware. In fact, most are not suited for use in hydroponics due to high levels of sodium and other impurities. Because of this, where possible, purchase coir that has been presoaked and pre-buffered. Failing this, the medium needs to be flushed with large amounts of water to remove sodium. Coco coir has a very strong cation exchange ability.This means that the medium can hold and release nutrient elements according to:

- The plant’s needs.

- The prevailing conditions in the medium itself.

Large amounts of potassium are naturally present in coco coir. Potassium competes with calcium and magnesium, so buffering and plant nutrition need to compensate for this. There are several nutrients that are specifically formulated with coco coir’s unique characteristics in mind. By using a nutrient specifically formulated for the coir-based system, you are ensuring that your plants are receiving the best possible nutrition.

Different growing techniques will determine the optimum system configuration for the coco coir system. Smaller plants are best grown in a Libra Tray system with Coir slabs. Larger plants, because of their larger root systems, will be ideally suited. to growing in 15 – 30 litre pots. Even larger plants will require 50 – 100 litre pots. Many growers use a 40% perlite, 60% coco coir mix in this system. In either case, either manual or automated watering can take place. Automated watering is highly recommended as this allows for many smaller feeds rather than one or two larger feeds done by hand. Feeding rates should be determined by the plant. A good way to ensure that the plant is getting what it needs is to allow for approximately 10% runoff from the overall nutrient delivered per feed (these feed rates can be increased to as much as 30% runoff to compensate for the buildup of salts in the media).

Let’s say you had 10 pots and you were delivering a litre per day to each pot; in this case you would ideally be getting 500 – 1000ml of run-off over the course of the day.

That is 10% of a litre = 100ml x 10 =1000.

You may like to increase this to as high as 15% – 20% runoff if you are using tap water with relatively high salt levels.

When you first put the plants in the system it is a good idea to hold back with feed rates. That is, keep the coir somewhat drier than what you would later on in the cycle.This is because it will force the roots to go off looking for food, ensuring that the root system establishes itself well in the early stages of growth. With this in mind you may want to start the feed regime at 60 – 100 ml per plant, per day. Use your discretion. If the plants begin wilting, in all likelihood they are not getting enough water/nutrient.

Automated Irrigation System

Automated irrigation of run-to-waste systems generally incorporates a digital timer (which can be set to 1 minute on/off intervals) with at least 6 on and off settings and a high-pressure pump that feeds through high-pressure line onto 30ml per minute drippers.This system ensures absolute control over the amount of water/nutrient that your plants receive.

Another method less commonly used is feeding from a standard water pump through 13mm line onto 4 mm lines with some form of flow regulator. Again, there is the need for a digital timer that allows for 1-minute settings. Using this system you can ideally bring feeds down to between 30-50 ml per minute.

Keep in mind here that run-to-waste mediums have high fluid retention rates so several smaller feeds throughout the duration of the day is the way to go, as this method maintains optimum oxygen/moisture ratio. In order for this method to work effectively, flow regulation is critical.

Rockwool

Rockwool is used on a large scale in greenhouses and a growing number of hobby growers are using it too. Rockwool is clean, sterile and very light. The medium itself does not provide any nutrients. As a result,the grower determines the exact level of nutrients for the plant. This increases the control over the growing process. Rockwool has a good water/oxygen ratio for the roots.Make holes in the plastic underside of the rockwool slab, ensuring that the lower end’s edge is cut to allow complete drainage.The Libra trays are on an angle to assist drainage.To enable this we allow for a 10mm difference between each side of the stand’s legs. Cut square holes in the plastic on top of the rockwool slab. Soak the slabs prior to use with a nutrient solution (EC: 1.4, pH: 5.3 — 5.5). The rockwool slabs are placed in a Libra tray with a corrugated base that allows for runoff and airflow. Attach the drainage pipes to the end of the tray.The excess water can now run into an outlet via these pipes: Regularly check to see that the pipes are not blocked and that runoff can flow freely.Three to five 7.5cm propagation blocks can be placed on each rockwool slab where the square holes have been cut. Use three to five rockwool trays per 600 Watt lamp.The watering process for rockwool systems can be easily automated. In the early stages feed amounts should be regular but minimal to ensure a healthy root system. Once the plants begin to thrive increase feed amounts to achieve a desired runoff of 20%. A drip-emitter is placed near each plant. The drip-emitters are connected to a capillary pipe, which in turn, is connected to a pump. The pump is controlled by an electronic timer that pumps water to the drip-emitters several times a day.The system can be easily expanded and can be made to fit into any growing area.

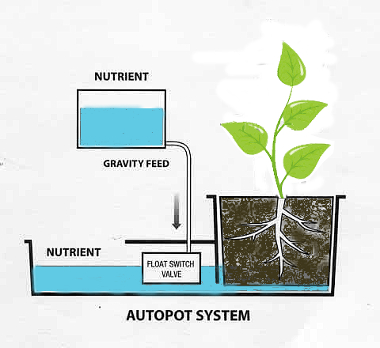

Wick Feed Systems – AQUAvalve/Autopot System

The Autopot system is effectively neither a recycling nor run-to- waste system. Instead nutrients are released to the plant/s via a gravity fed valve(AQUAvalve). Only when the entire amount of nutrient solution has been used does the valve release more nutrient. Through this system the plant is determining its own feed rates, and as a result there is no waste.

The key to this system is the AQUAvalve .The AQUAvalve is basically a float that doesn’t allow fluid through it until the reservoir that the valve is sitting in is completely empty. When this happens the valve reopens and allows more nutrient solution into the area where the pots are sitting.The plants then uptake the nutrient solution through capillary action that occurs naturally in the growing medium. This process is called the ‘Damping and Drying Out’ process.

This method of hydroponics is simplicity itself, offering a relatively minimal maintenance overhead. However, there are some restrictions in using the Autopot system, but there are solutions for most of them –

- Autopots do not offer the same level of control provided by more sophisticated systems

- The nutrient solution in the reservoir can become too warm or too cold due to the lack of nutrient solution volume (therefore, prone to temperature fluctuations that are determined by air temperatures). This can cause uptake problems for the plants (too cold), and potential root rot due to oxygen starvation (too warm)

- The roots can often grow into the reservoir. This problem is overcome by using root control discs, marix discs and potsocks

- Lack of flushing, due to the wick feeding nature of the system, can result in salt buildup in the media. (Ocassionally flushing water through the pots can compensate for this)

- Young plants initially placed into the system can face stress due to unsatisfactory levels of moisture in the media. To overcome this, top feed the plants twice a day for the first two weeks. A major benefit to strong and healthy plant growth is to use a root stimulant for the first week

On the plus side, this gravity fed system takes away the need for pumps and timers. The Autopot system tends to perform well and is ideally suited towards beginners and growers who like to keep things as simple as possible with minimal power usage.

So, there you have an overview of the main hydroponic systems under the two main types of run-to-waste or recycling. There really is no right or wrong answer as to which you select; it is more a matter of convenience. Run-to-waste systems require much less effort but do generate a disposal problem. Generally the choice you make will be based on a number of factors including maintenance levels, costs, space and the advantages and disadvantages of each system.